Poor Previous Repair Attempt

Why would this of happened?

This is not a GT Repair just for the record!

This repair should have been an easy repair if done correctly. Here we look at many reasons why it could have happened.

To a new repair technician this may look like a repairable damage as did the customer on this occasion. One of the hardest tasks as a trainer is training new techs how to recognise old damage. To be honest its something you learn with experience. Repairing this damage in the way described for fresh damage would result in zero improvement. Whilst it is obvious to us we will try to explain to help you when starting out.

How can we tell?

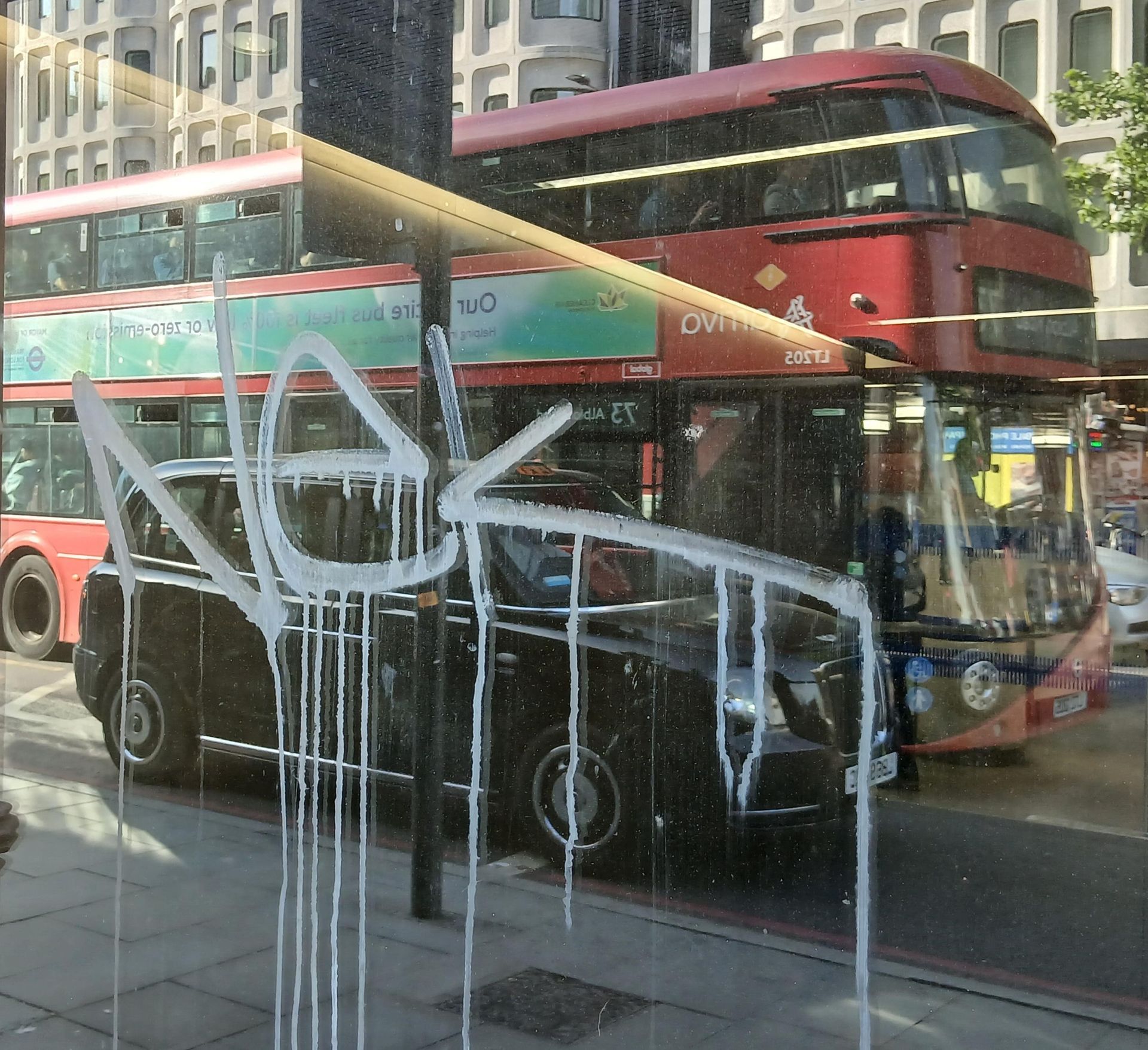

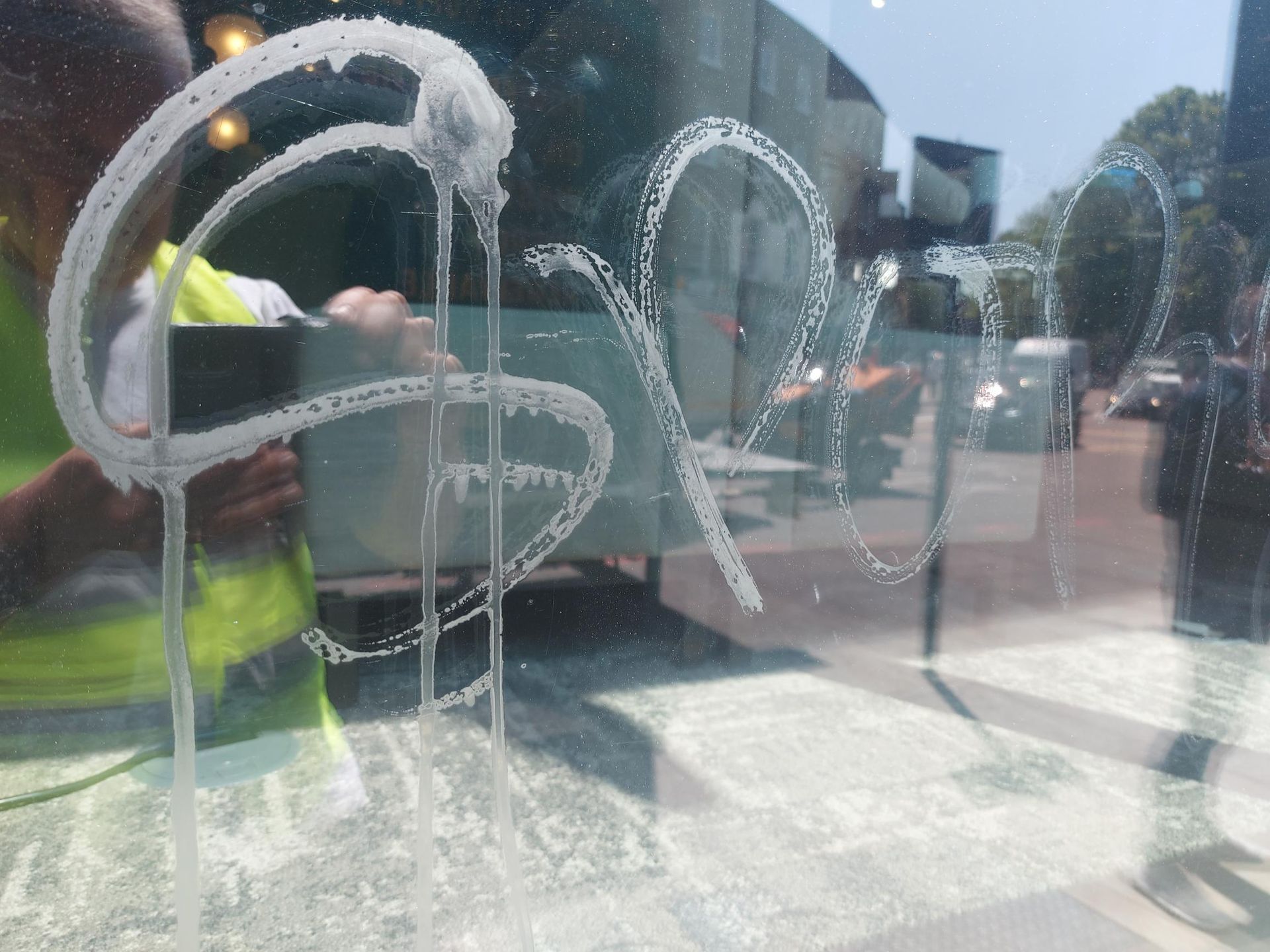

The centre impact is filled with pit fill.

It looks fairly smooth on the impact (centre) although it could have been crusty if it was an older repair.

If you drilled this impact it would powder up differently (cured resin) than if you was drilling glass without resin in it.

It would drill quite easily compared to glass.

You can not drill through the resin to reopen the damage

The clear ring in the middle is where resin did get in.

The outer ring with black in it is where the resin did not get in and remains as unrepaired damage.

The black showing still is trapped air

Why would this happen?

A DIY repair kit used.

Untrained technician-no accreditation to BS AU 242:b:2022

Substandard windscreen repair resin-not BS AU 242b:2022

Resin used could have been too thick and not of good quality

Poor quality equipment-Not BS AU 242b:2022

Old resin used and use by date surpassed. 2 years is the optimum peak performance date.

Heat was used in an attempt to make the resin thinner ( Naked flame is very common).

Some uncontrolled heat sources (Naked flame) closes the damage up to stop the resin flowing.

No UV shield used if it was done outside. Its started to cure and thus thicken the resin so that the resin stops flowing.

A none UV resistant syringe and needle used outside which has compromised the resin during the dispensing.

Air has not been removed before resin injected to create a void. Air out resin is known as VP-vacuum and pressure

Some systems try to squeeze resin into the void where air still exists. Resin in before air out known as displacement/direct pressure

Dirt and water present in the damage and adhesion has been compromised with contamination.

The water could have hydrophobic contamination (Rain X) within it which could have repelled the resin within the damage.

The points above are some of the factors which could have contributed to such a poor outcome. These types of repairs a

within most technicians capability if they comply with the 4M principal of BS AU 242b:2022 which has addressed some common bad practice.

An experienced technician may drill a fresh impact into the outer black ring and attempt some degree of improvement;