Safe windscreen repair at height

Ian Sprigg • June 4, 2020

New 2020 windscreen repair kits and why they are safer for use on commercial vehicles

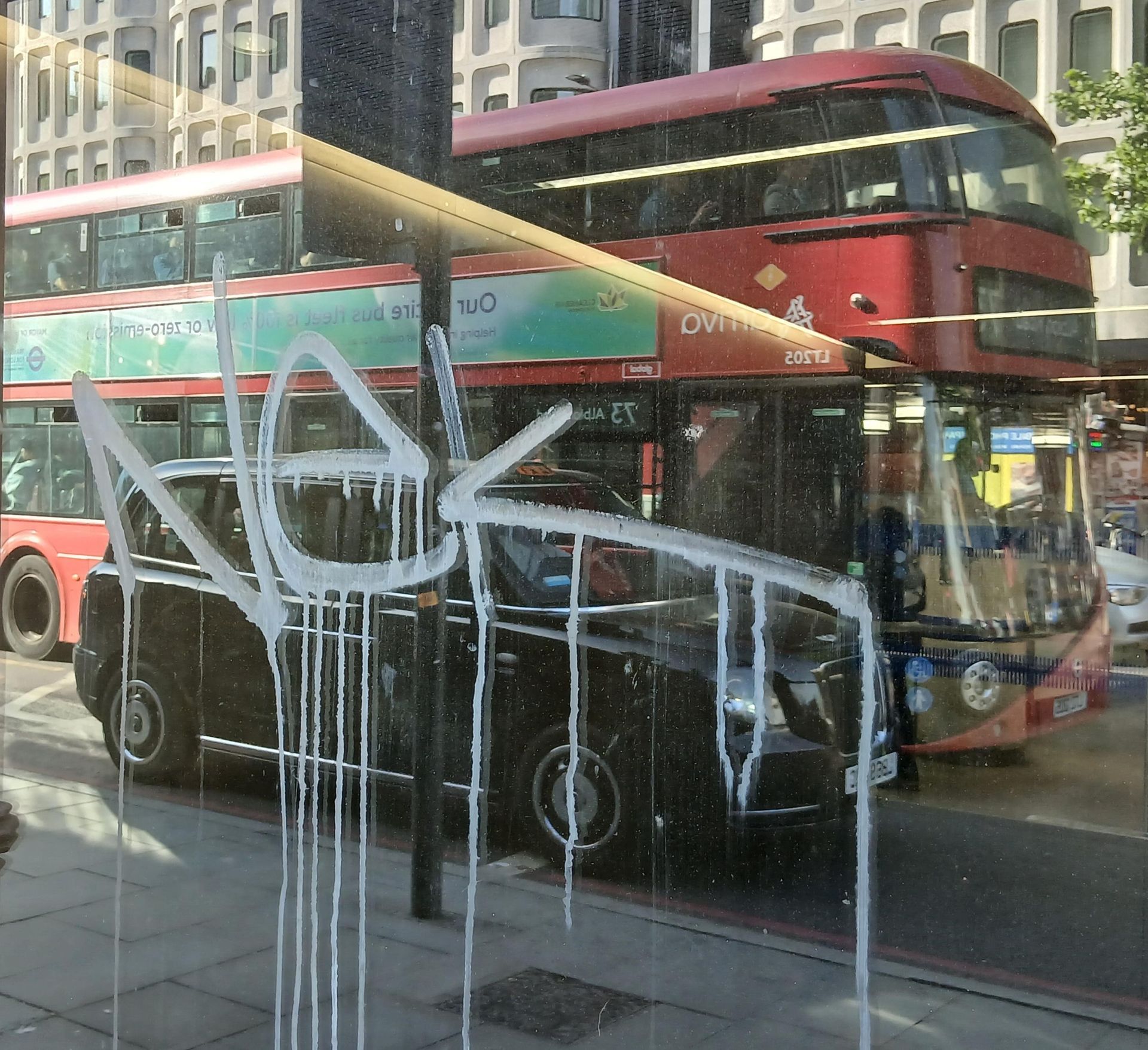

"If you check out the main image of this post you will see in the background the injector is placed at a height equivalent to that of the top of the stairs leading to the mezzanine floor"

Height can be significant like we established on this Scania windscreen at a head height of 15 feet and a significant height for a head injury on a concrete floor. Trailing cables in the working area are another safety issue in the workplace

Time on a step ladder can be reduced by quicker repair times and fewer movements on the step ladders. Fewer movements can be reduced by not having to go up and down the step ladders connecting 12 V cables for LED UV Curing or drills to power packs.

With GT Smart we only use windscreen repair injectors which can reduce the height exposure and windscreen repair time in half. In addition GT Smart only use rechargeable and cordless USB windscreen tools meaning once you are at height you can use your windscreen repair tools quickly and efficiently without continually having to go up and down the ladders to connect to power sources.

Incidentally as you are probably aware commercial vehicles are 24 V and as some technicians have experienced to their peril when working with 12 V windscreen repair tools they will short circuit if they connect to 12 V.

GT Smart has been there, experienced the limitations of wires and trailing cables whilst working at height and designed these unsafe risk factors out of our windscreen repair kits.